System Features

System Features

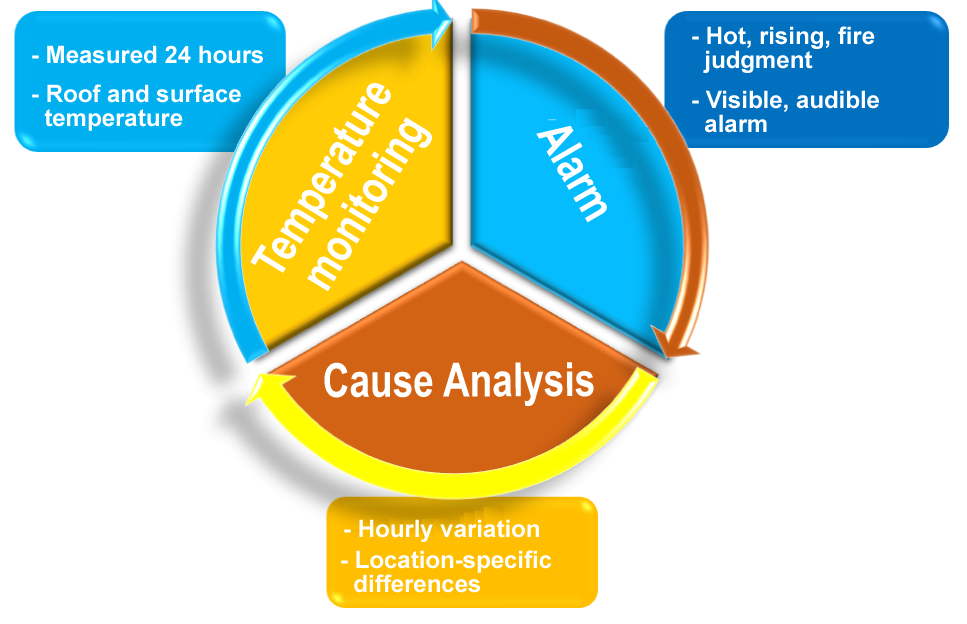

【Figure : System Features】

Ensure the monitoring performance in the operating conditions of the tank with all equipment (valve operation, Oil, Gas reserves, Flow).

- Easy-Map : The location of the alarm points are shown in the drawings.

- Easy-Analyzing : Temperature history, temperature compared with other facilities

- Easy-Maintenance : If you do not have a fiber-optic cable breakage Semi-permanent